Expert Synthetic Rubber Roofing Installation Services

Synthetic rubber roofing, commonly known as EPDM (ethylene propylene diene monomer), is a durable and flexible roofing material used primarily on flat or low-slope roofs. Its popularity stems from its excellent resistance to weathering, UV rays, and ozone, making it suitable for various climates. Synthetic rubber roofs typically have a lifespan of 25 to 30 years when properly installed and maintained. The installation process involves preparing the roof surface, laying out the rubber membrane, and securing it with adhesives or mechanical fasteners. Proper installation is essential to ensure the longevity and performance of the roofing system.

EPDM roofs are highly resistant to UV radiation, ozone, and extreme weather conditions, making them a long-lasting choice for flat roofs.

Synthetic rubber is highly resistant to water, mold, and mildew, which helps maintain the integrity of the roof over time.

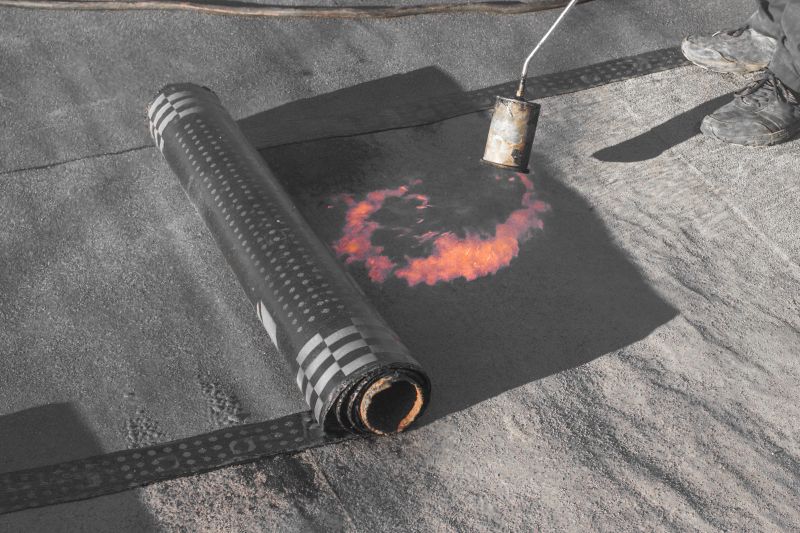

Installation of synthetic rubber roofing involves precise placement and sealing to ensure a seamless, waterproof surface.

A finished EPDM roofing system provides a sleek, uniform appearance with long-term durability.

Detail of the rubber membrane showing the secure sealing and edge finishing techniques.

The time needed for a professional to install a synthetic rubber roof varies depending on the size and complexity of the project. Typically, a standard flat roof can be completed within one to three days. The process begins with thorough surface preparation, followed by laying out the membrane, cutting to fit, and securing the material with adhesives or mechanical fasteners. Proper installation ensures the roof's resistance to leaks and damage, extending its service life.

Hiring a professional for synthetic rubber roof installation is recommended to ensure all steps are executed correctly. Experienced installers understand the nuances of the material, proper seam sealing, and weather considerations, which contribute to the roof's performance and longevity. Proper installation also minimizes the risk of future issues such as leaks or membrane tearing, ultimately protecting the building structure.

A completed synthetic rubber roof showcasing seamless edges and secure sealing.

Experts applying the rubber membrane onto a flat roof surface.

The benefits of choosing synthetic rubber roofing include its proven durability, ease of installation, and resistance to harsh weather conditions. These qualities make it a reliable choice for commercial and residential flat roofing applications. Properly installed, synthetic rubber roofs can provide decades of protection while requiring minimal maintenance.

For those interested in a synthetic rubber roofing system, it is advisable to contact a roofing professional to discuss specific project requirements. A detailed assessment can help determine the appropriate materials and installation techniques, ensuring a durable and effective roofing solution.