Best Timing for Synthetic Rubber Roofs

Synthetic rubber roof installations are most effective when performed during specific weather conditions. Optimal timing ensures proper adhesion, curing, and longevity of the roofing material. Understanding seasonal factors can help in planning installations to achieve the best results.

Installation should occur when temperatures are between 45°F and 85°F. Extreme cold or heat can affect the material's ability to bond properly.

Dry weather with minimal humidity is preferred. Rain or high humidity can interfere with adhesion and curing processes.

Spring and fall typically offer the most suitable weather conditions, avoiding the extremes of summer heat and winter cold.

Scheduling during moderate weather allows for adequate preparation, including surface cleaning and inspection.

Spring offers moderate temperatures and low humidity, ideal for installation.

While possible, high temperatures require careful planning to prevent material overheating.

Fall provides cooler temperatures and dry conditions, suitable for synthetic rubber roof installation.

Ways to make Synthetic Rubber Roof Installations work in tight or awkward layouts.

Popular materials for Synthetic Rubber Roof Installations and why they hold up over time.

Simple add-ons that improve Synthetic Rubber Roof Installations without blowing the budget.

High-end options that actually feel worth it for Synthetic Rubber Roof Installations.

Finishes and colors that play nicely with Synthetic Rubber Roof Installations.

| Season | Recommended Conditions |

|---|---|

| Spring | Moderate temperatures, low humidity, dry weather |

| Summer | Warm temperatures, caution with high heat |

| Fall | Cooler temperatures, dry conditions |

| Winter | Not recommended due to cold temperatures and potential moisture issues |

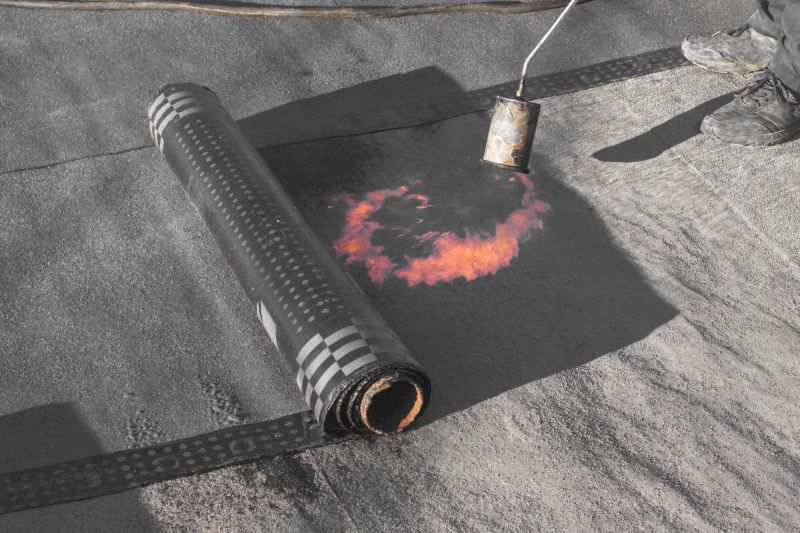

Synthetic rubber roofing, often made from ethylene propylene diene monomer (EPDM), is known for its durability, flexibility, and resistance to weathering. It is a popular choice for flat and low-slope roofs due to its ease of installation and long lifespan, often exceeding 30 years with proper maintenance. The material's resistance to UV rays, ozone, and temperature fluctuations makes it suitable for various climates. Proper installation during optimal weather conditions enhances adhesion and reduces the risk of future leaks or damage.

Statistics indicate that synthetic rubber roofs can withstand temperature swings from -40°F to 200°F, maintaining their integrity over decades. The installation process involves surface preparation, precise membrane placement, and secure sealing, which are best performed when environmental conditions support proper curing. Scheduling during favorable weather minimizes the likelihood of installation defects and prolongs the roof's service life.

Installation process showing surface preparation and membrane placement.

Completed installation with seamless membrane and secure edges.

Detail of the EPDM material's surface and sealing.

Final inspection to ensure proper installation and sealing.

Little measurements that prevent headaches on Synthetic Rubber Roof Installations day.

A 60-second routine that keeps Synthetic Rubber Roof Installations looking new.

A frequent mistake in Synthetic Rubber Roof Installations and how to dodge it.

Small tweaks to make Synthetic Rubber Roof Installations safer and easier to use.

Interested in synthetic rubber roof installations? Filling out the contact form can provide more information and help plan the project during the optimal season for best results.